Product classification

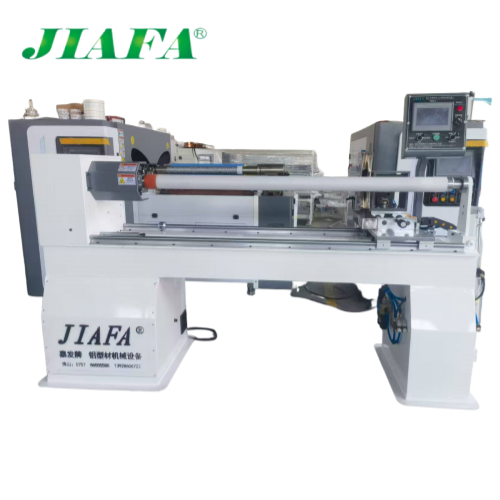

Bottom-row all-wheel-drive laminating machine

Our primary offerings include the Jiafa brand high-efficiency wood grain transfer oven, high-efficiency heat shrink packaging machine, film laminating machine, wrapping machine, and various packaging equipment. Additionally, we provide machinery and equipment for aluminum profiles. With a commitment to excellent quality and competitive pricing, we have emerged as a major supplier of heat shrink packaging machines in China.

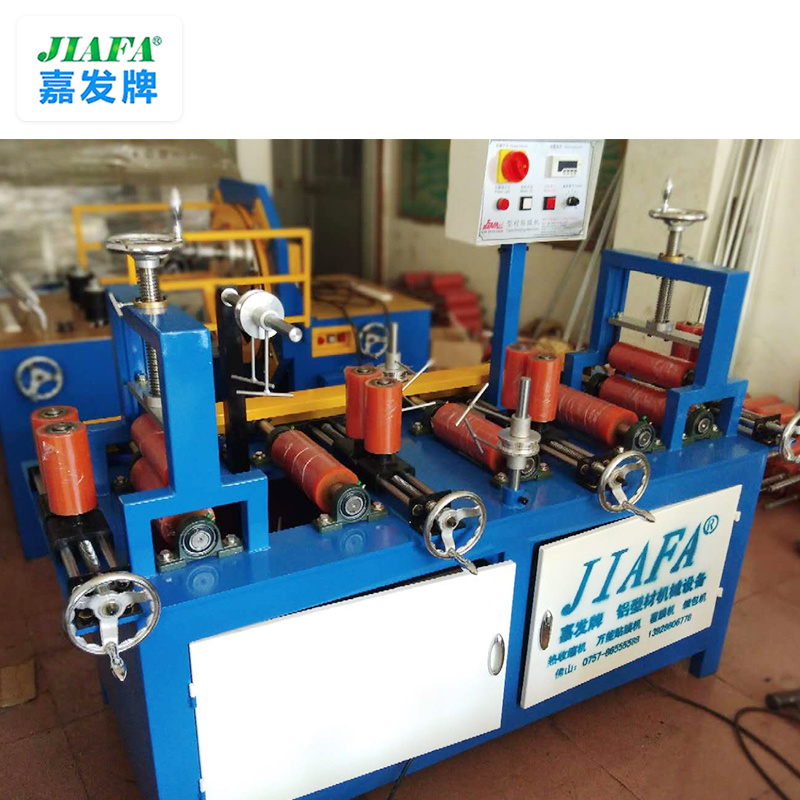

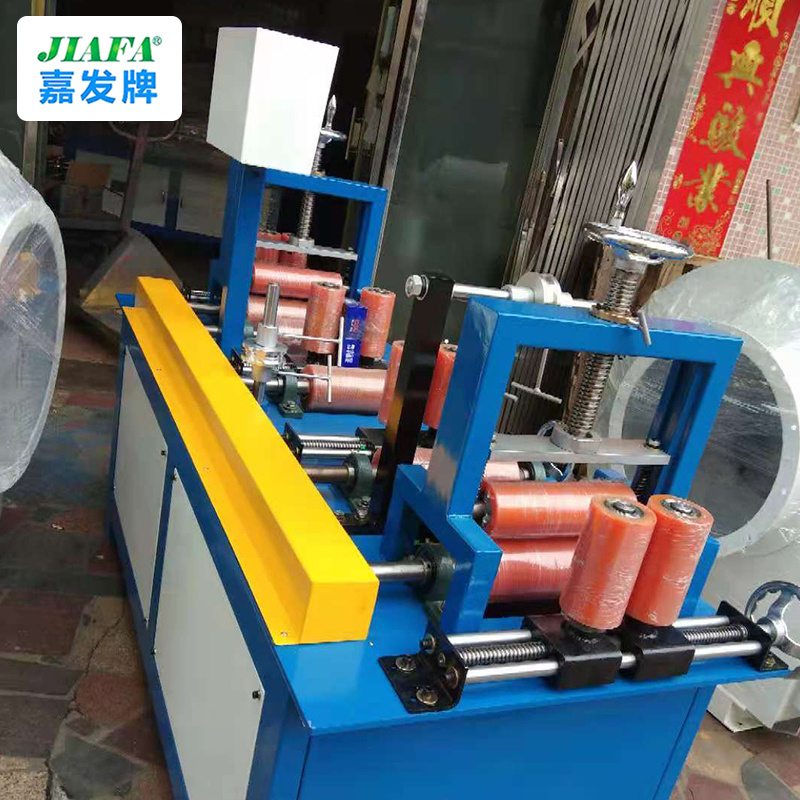

Categories: Aluminum Film Taping Machine

Product Introduction

[ All-Drive Stable Adhesion—Enhanced Protection: Aluminum Profile Bottom-Row All-Drive Film Applicator】

I. Core Product Introduction

The global aluminum profile market is becoming increasingly competitive, and high-quality protection and aesthetically pleasing designs have become core competitive advantages! For architectural door and window profiles, industrial equipment profiles, and aluminum profiles for new-energy vehicles, traditional film application often suffers from issues such as air bubbles, misalignment, and film delamination. Moreover, transporting long or heavy profiles can be unstable, and manual film application is inefficient and costly. Don't let film application defects reduce your product’s added value and cause you to miss out on orders!

Our bottom-row, fully-driven laminating machine—specifically designed for the aluminum profile industry—focuses on the needs of laminating long, heavy, and specially-shaped aluminum profiles. Leveraging our core “bottom-row, fully-driven synchronous conveying” technology, it precisely addresses industry pain points such as film misalignment, air bubbles, and low efficiency, ensuring bubble-free, flawless lamination that’s both stable and highly efficient. It strikes a perfect balance between protective performance and aesthetic quality, empowering aluminum profile companies to expand overseas with compliance and peace of mind.

II. Core Advantages

- Machine external dimensions (length × width × height, mm): 1850 × 860 × 1420.

- Roller dimensions: φ100 × 250 mm.

- Applicable power supply: 380V AC 50Hz; Motor power: 1.5KW.

- Film feeding speed: 0–280 m/min.

- Film application range: Film applied to all four sides—top, bottom, left, and right. Maximum profile size that can be covered: 200 mm wide × 140 mm high.

- Each entrance and exit is equipped with a 4-meter-long galvanized roller conveyor frame fitted with felt.

- Feed direction: Right in, left out (to be determined according to customer requirements).

- It is recommended to use a single-core 1-square-millimeter cable for machine wiring.

- All five rubber wheels on the bottom row of the machine are rotating.

III. Applicable Scenarios

- Architectural aluminum profiles: window and door profiles, curtain wall profiles, sunroom profiles, and more.

- Industrial aluminum profiles: aluminum profiles for new-energy vehicles, precision profiles for 3C electronics, high-end industrial equipment profiles, and more.

- Decorative aluminum profiles: home decoration profiles, outdoor landscape profiles, advertising and signage profiles, etc.

- Compatible Materials: Aluminum alloys, stainless steel, and various other aluminum profiles (compatible with profiles undergoing surface treatments such as powder coating, anodizing, and electrophoresis).

Leveraging advanced technology from Europe and America since 1991, specializes in producing the Jiafa brand packaging machine. Our production spans two workshops, covering 4500m² and 7000m², strategically located in Boai Road, Dali Town, Foshan City, and Longgao Road, Jiujiang Town, Foshan City. Notably, our offerings include the high-efficiency wood grain transfer oven, heat shrink packaging machine, film laminating machine, and wrapping machine, alongside various packaging equipment. Committed to excellence, competitive pricing, and top-notch quality, we've earned a reputation as a leading supplier of heat shrink packaging machines in China.

Key words:

Bottom-row all-wheel-drive laminating machine

Recommended Products