Product classification

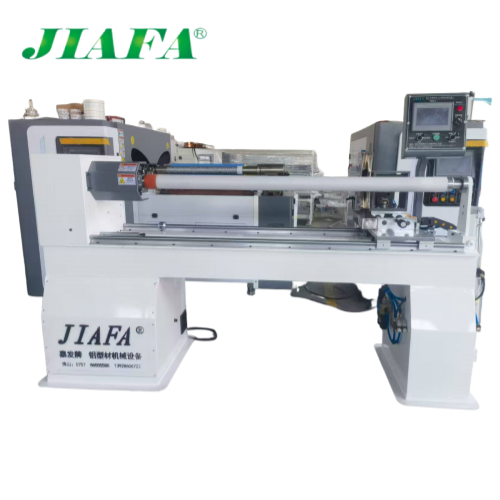

800-1500 Wide Door and Window Thermal Shrink Packaging Machine

Our primary offerings include the Jiafa brand high-efficiency wood grain transfer oven, high-efficiency heat shrink packaging machine, film laminating machine, wrapping machine, and various packaging equipment. Additionally, we provide machinery and equipment for aluminum profiles. With a commitment to excellent quality and competitive pricing, we have emerged as a major supplier of heat shrink packaging machines in China.

Categories: Aluminum Windoors Packing

Product Introduction

Door and Window Thermal Shrink Wrapping Machine: A Packaging Solution Empowering the Door and Window Industry

I. Introduction

With the booming development of the construction industry, doors and windows—as one of the key components—have seen their market demand steadily rise. To meet the demands of modern production and the market, automated and intelligent production equipment has become an essential choice for major door and window manufacturers. Among these, the thermal shrinkage packaging machine for doors and windows has garnered widespread attention due to its efficient, aesthetically pleasing, and environmentally friendly packaging method. This article will provide a detailed introduction to the structure, functions, advantages, and applications of thermal shrinkage packaging machines for doors and windows in the door and window industry.

II. Overview of Door and Window Thermal Shrink Wrapping Machines

The door and window heat-shrink packaging machine is a type of shrink-wrap equipment primarily used for heat-shrinking packaging of door and window products. Using heat-shrinking technology, a plastic film is tightly sealed onto the surface of doors and windows, achieving effects such as aesthetic appeal, dust protection, and moisture resistance.

III. Functional Features

1. Air-moving fans: Two high-speed, high-temperature-resistant fans of the imported “General” brand are installed above the heating chamber. (Note: The new model features an ultra-efficient, high-quality motor that outperforms the domestically produced YE3 series—it boasts exceptional efficiency, superior quality, high temperature resistance, high speed stability, and high rotational speed. Specifications: 220V–240V / 50–60Hz / 750W, 3,450 rpm, no-load current approximately 0.5A, operating current 1.5A, and temperature resistance up to 200°C.)

2. Electric heating tube and automatic temperature control: This system employs our factory’s high-efficiency, long-life, elliptical U-shaped side-insertion metal far-infrared electric heating tubes. The automatic temperature-control circuit is composed of AC contactors from brands such as “Mitsubishi” or “Fuji” from Japan, along with KKK temperature controllers. It operates on a 380V three-phase four-wire power supply, with a maximum temperature of ≤200℃ and a power rating of approximately 18 kW.

3. Drive motor and frequency converter: Install a high-quality brand motor with a power rating of ≥0.37 kW, paired with a high-performance frequency converter for stepless speed regulation. The speed is adjustable from 0 to 20 m/min, and the maximum conveyor load capacity is ≤80 kg.

4. Drive conveyor roller shaft: This is a heavy-duty type, machined from precision steel tubing with a diameter of 60 and a wall thickness of 5 (precision steel tubing used for manufacturing hydraulic and pneumatic cylinders). It features high-temperature resistance, excellent load-bearing capacity without deformation, and resistance to rusting. The center distance between conveyor roller shafts is approximately 200. The maximum load capacity of the conveyor is ≥100 kg.

5. Transmission and conveying direction: Equipped with a “forward/reverse” switch for users to easily and flexibly select the operating direction.

6. Quality and Performance: The machine boasts superior performance, fast packaging speed, no film damage, and delivers perfect shrink wrapping that is energy-efficient, high-performance, and capable of operating at low temperatures.

IV. Technical Parameters

1. Reference dimensions of the machine’s exterior (mm): 2000×1500×1450 (length × width × height);

2. Thermal chamber channel dimensions (mm): 1500 × 1200 × 300 (length × width × height);

3. The length of each machine’s inlet and outlet is 250 mm, and the conveying surface is approximately 730 mm above the ground.

4. 60-diameter roller, with 200mm spacing between each one.

V. Strengths Analysis

1. Enhance production efficiency: The door and window thermal shrink packaging machine enables high-speed, continuous packaging operations, significantly boosting production efficiency.

2. Reduce production costs: Minimize manual operation steps to lower labor costs; use environmentally friendly materials that align with national policy guidelines.

3. Enhance product quality: Thermal shrink packaging makes window and door products more aesthetically pleasing, dustproof, and moisture-resistant, thereby improving product quality.

4. Enhance market competitiveness: By adopting automated and intelligent packaging equipment, companies can improve their corporate image and strengthen their market competitiveness.

VI. Applications in the Doors and Windows Industry

The thermal shrink wrapping machine for doors and windows is widely used in various door and window manufacturing enterprises, such as those producing aluminum-clad wood doors and windows, thermally broken aluminum doors and windows, and PVC doors and windows. By applying thermal shrink wrapping to door and window products of different materials and specifications, the machine achieves effects such as aesthetic appeal, dust prevention, and moisture resistance, thereby meeting market demands.

Leveraging advanced technology from Europe and America since 1991, specializes in producing the Jiafa brand packaging machine. Our production spans two workshops, covering 4500m² and 7000m², strategically located in Boai Road, Dali Town, Foshan City, and Longgao Road, Jiujiang Town, Foshan City. Notably, our offerings include the high-efficiency wood grain transfer oven, heat shrink packaging machine, film laminating machine, and wrapping machine, alongside various packaging equipment. Committed to excellence, competitive pricing, and top-notch quality, we've earned a reputation as a leading supplier of heat shrink packaging machines in China.

Key words:

800-1500 Wide Door and Window Thermal Shrink Packaging Machine

Recommended Products