Product classification

Automatic Single Bundle Bagging Machine for Aluminum

Our primary offerings include the Jiafa brand high-efficiency wood grain transfer oven, high-efficiency heat shrink packaging machine, film laminating machine, wrapping machine, and various packaging equipment. Additionally, we provide machinery and equipment for aluminum profiles. With a commitment to excellent quality and competitive pricing, we have emerged as a major supplier of heat shrink packaging machines in China.

Categories: Aluminum Auto-Bagging Machine

Product Introduction

EQUIPMENT OVERVIEW

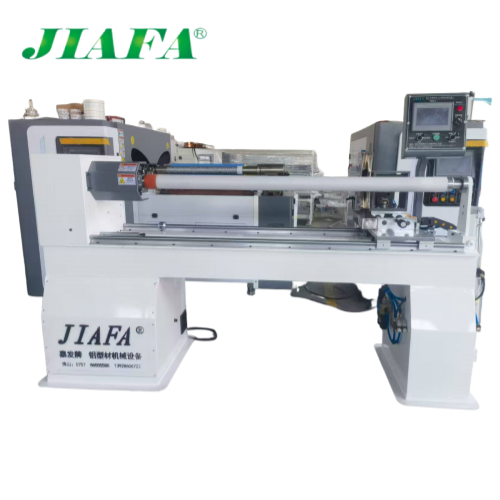

Single bundle bagging machine for aluminum is specifically designed for packaging aluminum profiles into bags. It is only suitable for use with shrink film bags.

This product features a unique design, ensuring safety and reliability, ease of use, enhanced work efficiency, energy savings, reduced labor requirements, and a low price point.

Aluminum Automatic Bagging Machine Features:

1. The main frame is constructed as an integrated structure, ensuring stable movement and smooth transfer during operation. This minimizes collisions and friction with aluminum profiles, thereby improving product yield rates.

2.The movement system employs servo motor drive with rack-and-pinion and slide rail guidance, delivering high positioning accuracy, low noise, and smooth braking.

3.Manual bagging is performed, with a cycle time of 15-25 seconds per bag. This reduces labor intensity and enhances efficiency.

4. Electrical Control System: Servo motors, frequency converters, touchscreens, and proximity switches utilize premium domestic brands. The PLC employs a domestic brand, with the electrical control system managed by PLC. An independent control system is adopted. Low-voltage electrical components are sourced from the renowned domestic brand Chint. The control system integrates a PLC with a 10-inch touchscreen. The equipment is equipped with safety emergency stop devices or buttons to ensure operator safety.

MAIN TECHNICAL PARAMETERS AND REQUIREMENTS

1. Model: Left-handed machine

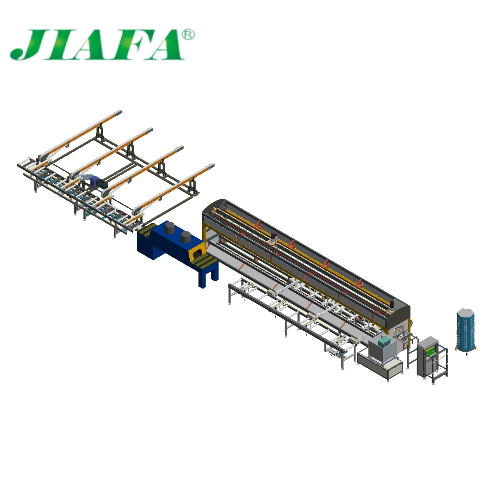

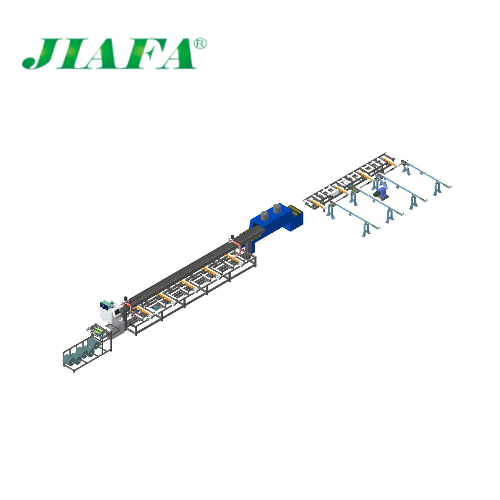

2. Equipment Footprint: Designed for 6.5-meter material length. Overall machine dimensions: Length 19000mm, Height 1680mm, Width 2200mm. With material storage conveyor rack: Total width 4 meters (Note: Storage rack width can be increased based on client factory space constraints).

3. Bundle Quantity: Single bundle per cycle

4. Profile Specifications: Maximum length: 4–6.8 meters; maximum width: 80–300 mm; maximum height: 40–200 mm.

5. Main Unit Input Power: Approx. 5 kW (excluding heat shrink machine power).

6. Production cycle: Approximately 15–25 seconds

7. Weight per bundle: Not exceeding 30 kg. Exceeding this weight will relatively slow down the bagging speed.

8. Shrink film bag thickness: ≥10C

PACKAGING PROCESS

Note: After heat shrinkage of the shrink film bag, a 20mm~30mm excess material tail remains.

Leveraging advanced technology from Europe and America since 1991, specializes in producing the Jiafa brand packaging machine. Our production spans two workshops, covering 4500m² and 7000m², strategically located in Boai Road, Dali Town, Foshan City, and Longgao Road, Jiujiang Town, Foshan City. Notably, our offerings include the high-efficiency wood grain transfer oven, heat shrink packaging machine, film laminating machine, and wrapping machine, alongside various packaging equipment. Committed to excellence, competitive pricing, and top-notch quality, we've earned a reputation as a leading supplier of heat shrink packaging machines in China.

Key words:

Automatic Single Bundle Bagging Machine for Aluminum

Recommended Products