Product classification

Aluminum Automated Material film Packaging Line

Our primary offerings include the Jiafa brand high-efficiency wood grain transfer oven, high-efficiency heat shrink packaging machine, film laminating machine, wrapping machine, and various packaging equipment. Additionally, we provide machinery and equipment for aluminum profiles. With a commitment to excellent quality and competitive pricing, we have emerged as a major supplier of heat shrink packaging machines in China.

Categories: Aluminum Auto-Packaging Line

Product Introduction

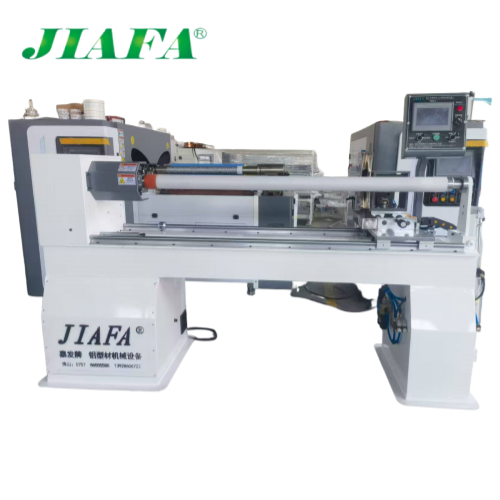

Full Automatic Film Packaging Production Line for Aluminum Profiles

MAIN FEATURE

1. This automatic film taping machine is specifically designed for manual/online automatic film laminating and cutting on aluminum profiles.

2. Featuring a unique design, it is safe and reliable, simple to operate, enhances work efficiency, saves energy, and conserves labor resources.

3. The new automatic film taping machine is suitable for applying film to the front surfaces and simple irregular surfaces of profiles.

4. This automatic film sticking machine for aluminum is simple to operate. The tension adjustment of the five vertical rollers uses a linked mechanism, making adjustments faster and more convenient than conventional film applicators. The equipment features a film-out alarm display. When the protective film is depleted or breaks during operation, the system detects the absence of film and automatically stops the machine while triggering an alarm display.

5. Quick and convenient film-changing mechanism: Used paper cores are directly removed after application. No need to press and tighten the cover after loading film, eliminating unnecessary work and boosting production efficiency.

6. Equipped with two curved frames featuring brushes and pressure rollers for film compression, designed for simple irregular profiles. This reduces air bubbles during application and enhances film quality on profiles.

7. The main unit employs servo motor drive with synchronous belt transmission, delivering precise positioning, low noise, and smooth braking.

8. This automatic film laminating equipment for aluminum profile requires only one operator for feeding, with each profile taking 4–6 seconds to process. This reduces labor requirements and boosts operational efficiency.

MAIN STRUCTURAL COMPONENTS

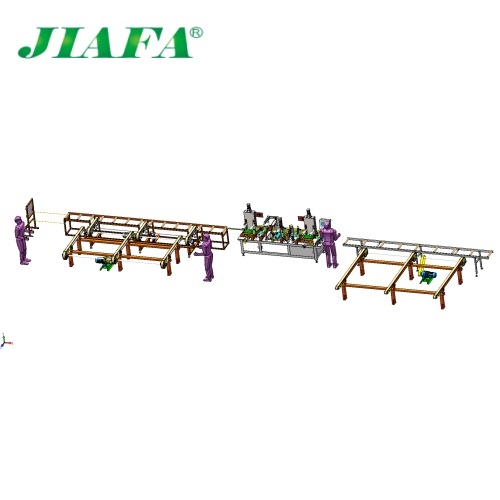

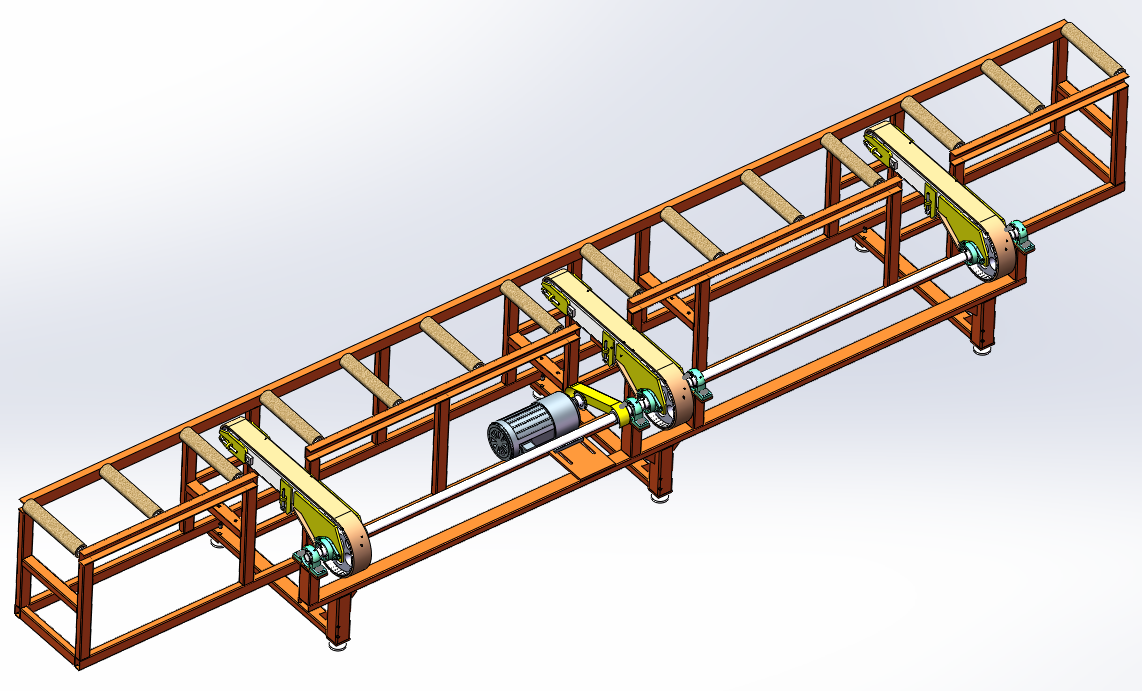

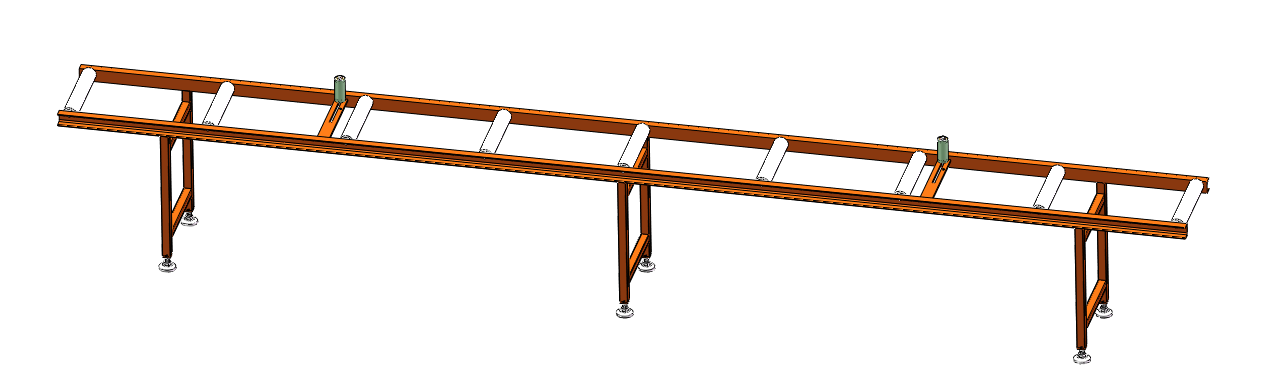

The automatic film sticking machine for aluminum consists of a feed storage conveyor rack, feed roller rack, film laminating machine main unit, lifting and translating device, and discharge conveyor rack.

FILM TAPING PROCESS

Operational Procedure:

Profile is placed on the feed conveyor storage rack (or stored on a flatbed cart) → Manually transfer profiles to the feed roller rack → Feed into the inlet → Servo motor drives synchronous belt to feed and apply film → Material passes through sensors for positioning → Automatic serrated film cutting → Second profile enters → Servo motor drives synchronous belt to separate two profiles → Film-coated profiles automatically discharged → Lifting and translating device → Discharge conveyor rack → Manually bundle materials.

MAIN TECHNICAL PARAMETERS AND REQUIREMENTS

1. Model: Left-handed machine

2. Equipment footprint: Designed for 7-meter material length. Main unit dimensions: 3150mm (L) × 780mm (W) × 1500mm (H). Total length with feed/discharge conveyors: approx. 19 meters.

3. Single material weight: <12kg/piece.

4. Film Cutting Quantity: Single piece per operation.

5. Profile Specifications: Maximum length: 4m–7m; maximum width: 220mm; maximum height: 150mm.

6. Film Specifications: Maximum width 20–200mm, maximum height 20–150mm.

7. Film Cutting Quality: Requires smooth cut edges with protective film extending ±5mm beyond profile ends.

8. Film Cutting Mode: Manual/automatic cutting; (Cutting cylinder depth manually adjustable per film thickness).

9. Film absence detection: Automatic detection and alarm display for film absence or mid-cut breakage.

10. Film loading device: Quicker and more convenient film loading/changing than standard models.

11. Input power: Approx. 3KW (excluding conveyor frame power).

12. Aluminum profile wall thickness for film application: 1.0mm or above.

13. Film application shape: Flat four-sided film (Note: Manual mode can be used for irregular profiles).

14. Single-side film application; when film runs out during profile application, the machine can reverse to reload film.

15. Filming speed: 0–2 m/s; 10–15 profiles per minute. Filming speed slows proportionally when exceeding parameters.

16. Feeding method: Manual feeding

17. Vertical roller and pressure roller clamping method: Electric adjustment

CORE APPLICATION SCENARIOS(BY AlUMINUM PROFILE HANDLING STAGE)

1. Aluminum Profile Production Workshop: “Immediate Protection, Quality Assurance at Source”

2. Aluminum Profile Deep Processing Stage: “Dual Protection Before and After Processing”

3. Warehousing and Long-Distance Transportation: “Damage and Moisture Prevention, Reduced Losses”

4. Pre-Assembly of Finished Products: “Maintain Cleanliness, Minimize After-Sales Service”

5. Customized Protection Scenarios: “Precision Matching for Special Requirements”

PRIMARY INDUSTRIES SERVED(BY ALUMINUM PROFILE APPLICATION AREAS)

1. Construction Industry: Door and window profiles (thermal break aluminum, system windows), curtain wall profiles, balcony railings, sunroom frames

2. Home Furnishings & Building Materials Industry: Wardrobe/cabinet aluminum frames, furniture legs, bathroom partition profiles, custom home aluminum frames

3. Transportation Industry: Automotive aluminum profiles (roof racks, door frames), high-speed rail interior profiles (seat frames, window frames), ship deck aluminum profiles

4. Electronics & Appliances Industry: Heat sink profiles (LEDs, servers), equipment enclosures (instruments, charging stations), electronic brackets

5. Industrial Equipment Industry: Aluminum profiles for automated assembly lines, machine guardrails, workshop partition profiles, medical device frames

6. New Energy Industry: Photovoltaic mounting bracket profiles, aluminum enclosures for energy storage equipment, aluminum frames for power battery packs

7. Decoration & Renovation Industry: Aluminum profiles for interior ceilings, decorative profiles for accent walls, aluminum frames for exhibition booths

8. Export Trade Industry: Various export-grade aluminum profiles (distributed to Europe, America, Southeast Asia, and other regions)

Leveraging advanced technology from Europe and America since 1991, specializes in producing the Jiafa brand packaging machine. Our production spans two workshops, covering 4500m² and 7000m², strategically located in Boai Road, Dali Town, Foshan City, and Longgao Road, Jiujiang Town, Foshan City. Notably, our offerings include the high-efficiency wood grain transfer oven, heat shrink packaging machine, film laminating machine, and wrapping machine, alongside various packaging equipment. Committed to excellence, competitive pricing, and top-notch quality, we've earned a reputation as a leading supplier of heat shrink packaging machines in China.

Key words:

Aluminum Automated Material film Packaging Line

Recommended Products