Product classification

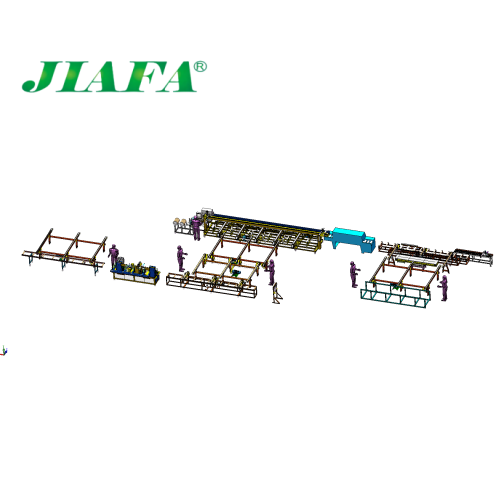

Aluminum Automated Material Film Bagging Packaging Line

Our primary offerings include the Jiafa brand high-efficiency wood grain transfer oven, high-efficiency heat shrink packaging machine, film laminating machine, wrapping machine, and various packaging equipment. Additionally, we provide machinery and equipment for aluminum profiles. With a commitment to excellent quality and competitive pricing, we have emerged as a major supplier of heat shrink packaging machines in China.

Categories: Aluminum Auto-Packaging Line

Product Introduction

Aluminum Packing Automatic Production Line

MAIN FEATURE

1. The aluminum film bagging production line is designed and developed based on market demand, primarily to meet the multi-specification requirements for aluminum profiles. It features a simple structure, safe and stable operation, easy handling, minimal factory footprint, reduced labor requirements, and energy-efficient performance.

2. Film application results: Film lies parallel to the profile without tilting or bubbling. Film cut-off point does not exceed 5mm. Automatic alarm triggers for film breakage. Easy film loading and alignment.

3. Suitable for bagging multi-specification aluminum profiles. Ensures no loosening, bag rupture, or air bubbles.

MAIN STRUCTURAL COMPONENTS

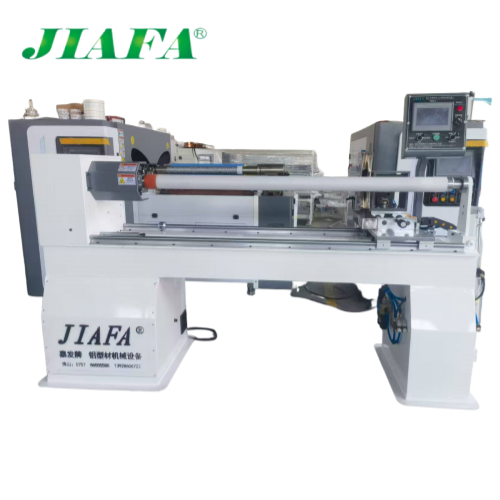

1. The equipment consists of an aluminum automatic film laminating machine, single bundle bagging machine for aluminum, heat shrink wrapping machine, and material discharge transfer device.

2. Electrical Control System—Utilizes PLC control. The electrical control system employs an independent control system, employing a PLC + touchscreen configuration to manage the entire system. Conveyor motors and reducers are controlled by variable frequency drives, with control signals issued by the PLC. Users can input user parameters and modify system parameters via the touchscreen.

MAIN TECHNICAL PARAMETERS AND REQUIREMENTS

Automatic Film-Taping Single-Bundle Bagging Machine for profile packaging.

The basic specifications are as follows:

1 Equipment layout dimensions:L30000mm* W 8200mm* H 1650mm

2 Film profile length:4000mm-7000mm

3 Maximum profile film specification:W200mm、H100mm

4 Minimum Profile Width ≥20mm

5 Minimum Profile Height ≥20mm

6 Maximum Profile Weight 15KG/piece

7 Thinnest Point of Single Profile ≥1.0mm

8 Total Equipment Power 3KW

9 Film application speed: 14-17 pieces per minute

10 Bagged profile length: 4000mm-7000mm

11 Maximum profile dimensions: Width 80-250mm, Height 40-160mm

12 Maximum profile weight: 30KG/bundle

13 Bagging speed: 3 bundles per minute

APPLICATION SCENARIOS

This equipment employs an integrated “automatic film laminating + single bundle bagging” process that not only addresses the protective needs of aluminum profiles against scratches and oxidation but also enables standardized storage through bundle bagging. It adapts to the entire lifecycle of aluminum profiles—from production line to warehousing, transportation, further processing, and final delivery—and is particularly suited for scenarios involving mass production, long-length profiles, and high-protection requirements.

I. Aluminum Profile Production Workshop: Off-line “Protection + Packaging” Saves Labor and Boosts Efficiency

II. Aluminum Profile Storage: Bundled and Bagged for Easy Management, Moisture and Dust Protection Reduces Losses

III. Long-Distance Transportation and Logistics Distribution: Sealed Protection Against Jostling Minimizes Cargo Damage Disputes

IV. Pre-Processing Stage for Aluminum Profile Deep Processing: Pre-Treatment Protection Reduces Processing Waste

V. End-Customer Delivery: Standardized packaging elevates perceived quality and enhances brand reputation.

COMPETITIVE ADVANTAGES

The combination of “protection + efficiency + management” is particularly suited for the following scenarios:

1. Manufacturers requiring batch processing of 4-7 meter long, ≥20mm wide/high profiles;

2. Small-to-medium profile factories focused on reducing labor costs and minimizing storage/transportation losses;

3. Enterprises with export requirements needing to meet environmental and sealing protection standards;

4. Home furnishing/industrial profile users involved in deep processing requiring guaranteed surface cleanliness.

Leveraging advanced technology from Europe and America since 1991, specializes in producing the Jiafa brand packaging machine. Our production spans two workshops, covering 4500m² and 7000m², strategically located in Boai Road, Dali Town, Foshan City, and Longgao Road, Jiujiang Town, Foshan City. Notably, our offerings include the high-efficiency wood grain transfer oven, heat shrink packaging machine, film laminating machine, and wrapping machine, alongside various packaging equipment. Committed to excellence, competitive pricing, and top-notch quality, we've earned a reputation as a leading supplier of heat shrink packaging machines in China.

Key words:

Aluminum Automated Material Film Bagging Packaging Line

Recommended Products