Product classification

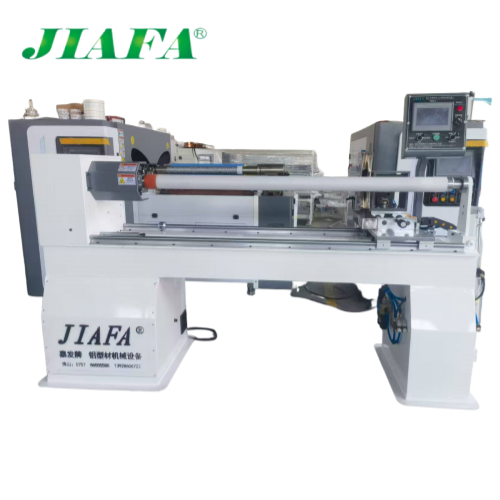

Pillow Type Packing Machine For Aluminum

Our primary offerings include the Jiafa brand high-efficiency wood grain transfer oven, high-efficiency heat shrink packaging machine, film laminating machine, wrapping machine, and various packaging equipment. Additionally, we provide machinery and equipment for aluminum profiles. With a commitment to excellent quality and competitive pricing, we have emerged as a major supplier of heat shrink packaging machines in China.

Categories: Aluminum Flow Pack Machine

Product Introduction

Horizontal Shrink Pack Machine for Aluminum

The aluminum pillow shrink packing machine is an automated packaging device specifically designed for long, strip-shaped aluminum profiles. It achieves efficient, standardized packaging through continuous film forming, heat sealing, and cutting processes.

MAIN PERFORMANCE

-

1. Servo 3 motors, PLC controller,flexible bag length setting and cutting,saving time and film.

-

2. Human-machine interface, convenient and quick parameter settings, when the product is sensed by the sensor, then it will be packing automatically, otherwise, it will be stopped.

-

3. Self diagnosis failure function, failure displayed clearly.

-

4. High sensitive optical electric color mark tracking system and digital input cut position, which make the sealing and cutting more accurate.

-

5. Separated PID control system for temperature, suitable for various packing materials.

-

6. Stopping the machine in selected position, no sticking on the knife and no waste of the film.

-

7. Simple driving system, reliable working, convenient maintenance.

-

8. All controlled by program, convenient for function adjusting and upgrading.

-

9. Packaging formula storage function, one-click read, easy to adjust.

USE RANGE

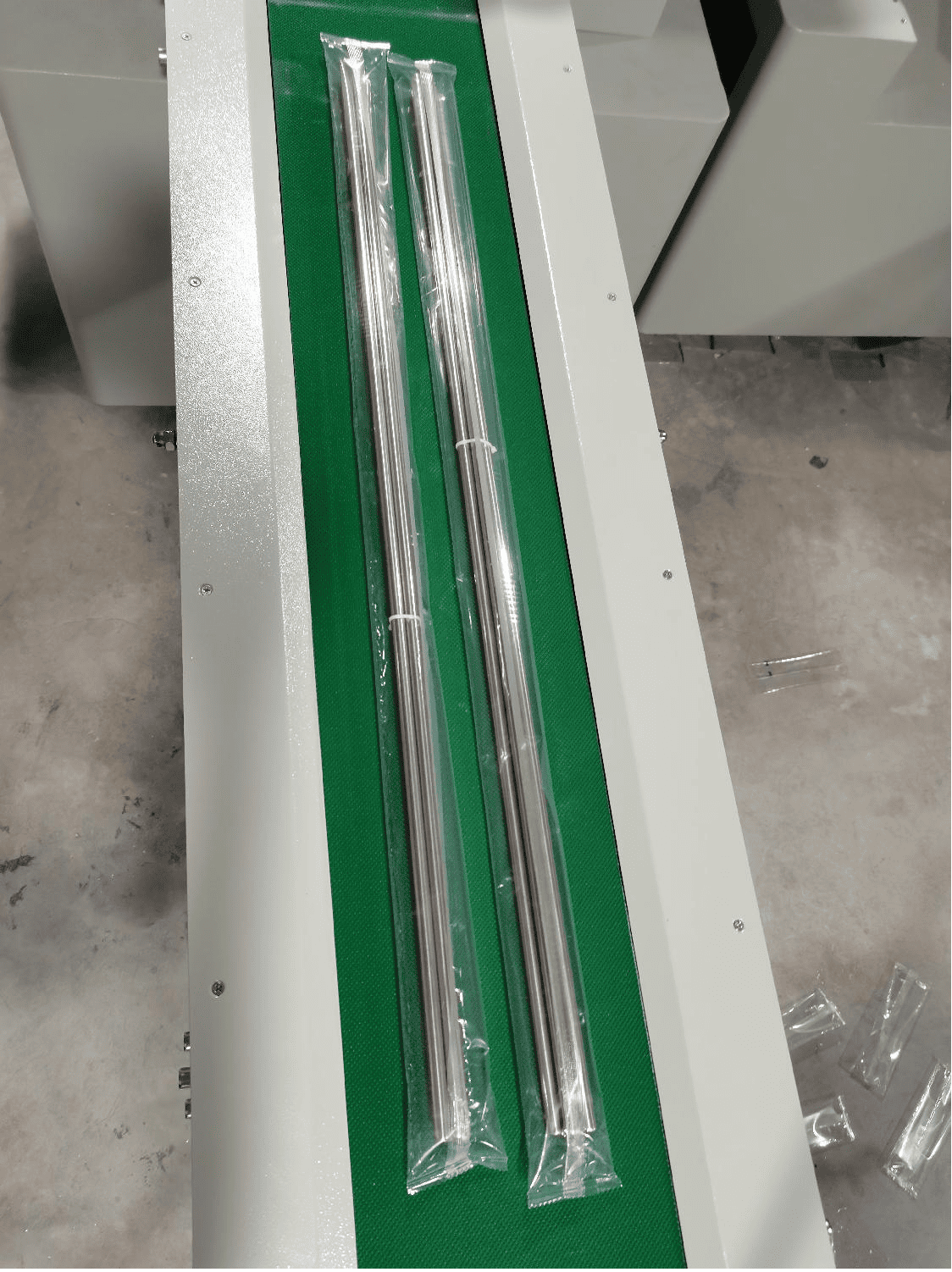

1. Widely used in automated production lines for flow packaging across industries such as hardware, food, daily chemicals, and pharmaceuticals.

2. Hardware: Guide rail packaging, hardware tools, aluminum profiles (1-10 meters), pipe packaging, etc. Automatically senses bag length based on product dimensions.

PROFILE PACKING PROCESS

MAIN TECHNICAL PARAMETERS AND REQUIREMENTS

- Film Width Max.340mm

- Bag length ≧150mm

- Bag width 50~150mm

- Product Height Max.60mm

- Film roll diameter Max.320mm

- Packing speed ≦25/M/min

- Power Specifications 220V,50/60HZ,2.4KW

- Machine size (L)1560×(W)850×(H)1520mm

- Approximately Weight 600Kg

- Entrance conveyor rack (L)3150×(W)550×(H)1520mm

- Export conveyor rackt (L)3150×(W)550×(H)1520mm

COMMON FAULTS AND SOLUTIONS

1. Poor Sealing or Burning

- Cause: Improper temperature setting (PE film recommended 120-180°C), insufficient pressure, or too short sealing time.

- Solution: Gradually adjust temperature (5-10°C increments), inspect heating elements for wear, increase spring pressure.

2.Film wrinkling or misalignment

- Cause: Uneven tension, misaligned guide rollers, or improper roll installation.

- Solution: Recalibrate tension control system, adjust guide roller angles, ensure roll center aligns with machine axis.

3.Blade fails to cut or cuts unevenly

- Cause: Blade wear, motor failure, or loose drive chain.

- Solution: Replace blades with imported materials ,check motor belt tension, clean accumulated dust from chain.

Leveraging advanced technology from Europe and America since 1991, specializes in producing the Jiafa brand packaging machine. Our production spans two workshops, covering 4500m² and 7000m², strategically located in Boai Road, Dali Town, Foshan City, and Longgao Road, Jiujiang Town, Foshan City. Notably, our offerings include the high-efficiency wood grain transfer oven, heat shrink packaging machine, film laminating machine, and wrapping machine, alongside various packaging equipment. Committed to excellence, competitive pricing, and top-notch quality, we've earned a reputation as a leading supplier of heat shrink packaging machines in China.

Key words:

Pillow Type Packing Machine For Aluminum

Recommended Products