Product classification

Heat Seal Packing Machine Shrink Pack Equipment for Windoors

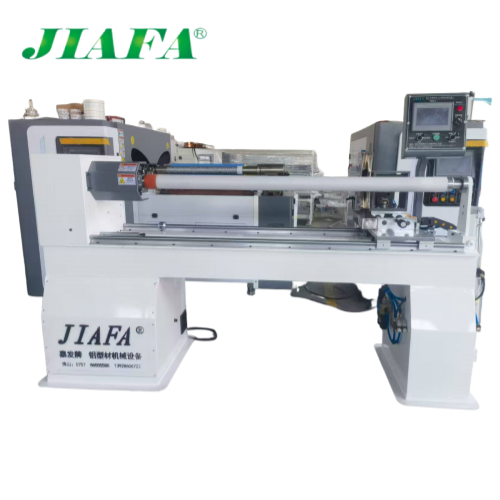

Our primary offerings include the Jiafa brand high-efficiency wood grain transfer oven, high-efficiency heat shrink packaging machine, film laminating machine, wrapping machine, and various packaging equipment. Additionally, we provide machinery and equipment for aluminum profiles. With a commitment to excellent quality and competitive pricing, we have emerged as a major supplier of heat shrink packaging machines in China.

Categories: Aluminum Windoors Packing

Product Introduction

**Heat Seal Packing Machine Shrink Pack Equipment for Windoors**

In the world of packaging, efficiency and reliability are paramount. As industries strive to improve their production lines, the demand for advanced packaging equipment has grown significantly. Among these innovations, heat seal packing machines have emerged as a critical component in various sectors, including food, pharmaceuticals, and consumer goods. This article will explore the significance of heat seal packing machines, particularly focusing on their application in shrink pack equipment for windoors.

**Understanding Heat Seal Packing Machines**

Heat seal packing machines are designed to create airtight seals on packaging materials. They utilize heat to melt and bond layers of plastic or other materials together, ensuring that products are securely enclosed. This method of sealing not only enhances the shelf life of products but also provides a tamper-proof barrier that protects against contamination.

These machines are widely used across various industries due to their versatility and effectiveness. They can accommodate different types of packaging materials, including polyethylene, polypropylene, and other thermoplastic films. As a result, manufacturers can choose the most suitable materials for their products, ensuring optimal protection and presentation.

**The Role of Shrink Pack Equipment**

Shrink pack equipment complements heat seal packing machines by providing an additional layer of protection. Shrink wrapping involves encasing products in a plastic film that shrinks tightly around them when exposed to heat. This process is particularly beneficial for items that require additional stability and protection during transportation and storage.

For windoors, which are a combination of windows and doors, shrink pack equipment is essential. These products are often large and cumbersome, making them vulnerable to damage during handling and shipping. By utilizing shrink wrap, manufacturers can safeguard windoors from scratches, dust, and moisture, ensuring they arrive at their destination in pristine condition.

**Benefits of Using Heat Seal Packing Machines for Windoors**

1. **Enhanced Protection**: One of the primary advantages of using heat seal packing machines for windoors is the enhanced protection they offer. The airtight seal prevents environmental factors from compromising the integrity of the product. This is particularly important for windoors, which are often made of materials that can be affected by humidity and temperature changes.

2. **Cost-Effectiveness**: Heat seal packing machines can lead to significant cost savings for manufacturers. By reducing the risk of product damage during transit, companies can minimize losses associated with returns and replacements. Additionally, the efficiency of these machines allows for faster production times, leading to increased output and profitability.

3. **Improved Aesthetics**: Packaging plays a crucial role in product presentation. Heat seal packing machines can create sleek and professional-looking packages that enhance the appeal of windoors. This is especially important in competitive markets where first impressions can influence purchasing decisions.

4. **Versatility**: Heat seal packing machines are adaptable to various product sizes and shapes. This versatility makes them an ideal choice for manufacturers of windoors, as they can accommodate different designs and specifications without the need for extensive modifications.

5. **Sustainability**: Many heat seal packing machines are designed to work with recyclable materials, contributing to a more sustainable packaging solution. As consumers increasingly prioritize eco-friendly practices, manufacturers can enhance their brand image by adopting sustainable packaging methods.

**Choosing the Right Heat Seal Packing Machine for Windoors**

When selecting a heat seal packing machine for windoors, several factors should be considered.

1. **Production Volume**: Manufacturers should assess their production volume to determine the appropriate machine size and capacity. High-volume operations may require larger machines with faster sealing speeds, while smaller manufacturers may opt for compact models.

2. **Material Compatibility**: Different windoors may require specific types of packaging materials. It is essential to choose a heat seal packing machine that is compatible with the materials being used to ensure optimal sealing performance.

3. **Ease of Use**: User-friendly machines can significantly enhance productivity. Manufacturers should look for machines that offer straightforward operation and maintenance, reducing the likelihood of downtime and training costs.

4. **Cost**: While investing in a heat seal packing machine is crucial, manufacturers should also consider the total cost of ownership. This includes not only the initial purchase price but also maintenance, operational costs, and potential savings from reduced product damage.

5. **Technical Support**: Reliable technical support from the manufacturer is vital for addressing any issues that may arise during operation. Companies should choose suppliers known for their customer service and support capabilities.

**Conclusion**

Heat seal packing machines and shrink pack equipment play an indispensable role in the packaging process for windoors. By providing enhanced protection, cost savings, improved aesthetics, versatility, and sustainability, these machines are essential for manufacturers looking to optimize their production lines. As the demand for efficient packaging solutions continues to grow, investing in advanced heat seal packing technology will enable manufacturers to stay competitive in an ever-evolving market. Ultimately, the right heat seal packing machine can significantly impact the success of windoor products, ensuring they reach consumers in perfect condition.

Leveraging advanced technology from Europe and America since 1991, specializes in producing the Jiafa brand packaging machine. Our production spans two workshops, covering 4500m² and 7000m², strategically located in Boai Road, Dali Town, Foshan City, and Longgao Road, Jiujiang Town, Foshan City. Notably, our offerings include the high-efficiency wood grain transfer oven, heat shrink packaging machine, film laminating machine, and wrapping machine, alongside various packaging equipment. Committed to excellence, competitive pricing, and top-notch quality, we've earned a reputation as a leading supplier of heat shrink packaging machines in China.

Key words:

Heat Seal Packing Machine Shrink Pack Equipment for Windoors

Recommended Products