Product classification

Automatic Profile Film Sticking Machine Film Tapping Machine

Our primary offerings include the Jiafa brand high-efficiency wood grain transfer oven, high-efficiency heat shrink packaging machine, film laminating machine, wrapping machine, and various packaging equipment. Additionally, we provide machinery and equipment for aluminum profiles. With a commitment to excellent quality and competitive pricing, we have emerged as a major supplier of heat shrink packaging machines in China.

Categories: Aluminum Auto-Film Sticking Machine

Product Introduction

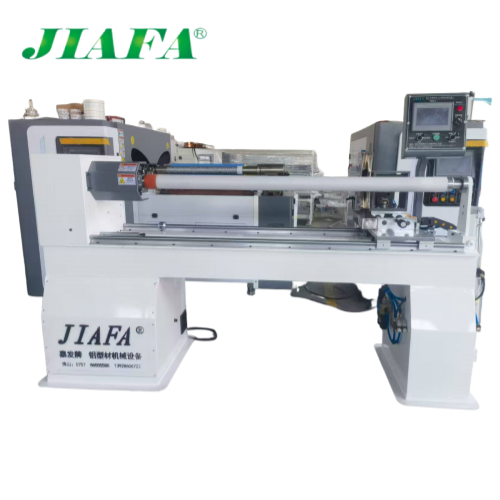

Aluminum Automatic Film Laminating Machine Aluminum Processing Machinery

The automatic film laminating machine for aluminum profiles is an automated device specifically designed for surface protection of aluminum profiles. It is primarily used to apply protective film during the processing, transportation, and storage of aluminum profiles, preventing surface scratches, contamination, or oxidation.

MAIN FEATURE

1. The equipment is designed and developed according to the market demand, mainly to be safe and reliable, simple operation, reduce the location of the workshop, reduce the production labor force, energy saving and efficient.

2.Film effect: film and profile parallel no tilt no foaming, cutting film port does not exceed 5MM, broken film no film automatic alarm, easy to install film correction.

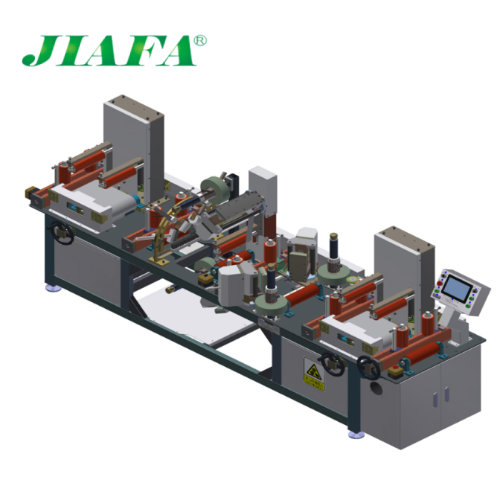

MAIN STRUCTURAL COMPONENTS

1. Feed storage and conveying device, feeding device, manual/ automatic film placement and cutting system, lifting device, discharge translation platform, discharge storage and conveying device.

2. Electronic control system -- using PLC control. The electrical control system adopts a set of independent control system, using PLC+ touch screen to control the whole system, the loading and unloading motor reducer is controlled by the inverter, and the control signal is issued by the PLC. Users can enter user parameters and modify system parameters on the touch screen.

MAIN TECHNICAL PARAMETERS AND REQUIREMENTS

Automatic film laminating machine for aluminum profile for profile packaging.

The basic specifications are as follows:

1 Equipment size:L1800mm* W 400mm* H 1580mm

2 Film profile length:3500mm-7000mm

3 Maximum profile film specification:W200mm、H150mm

4 Profile minimum width:≥ 20mm

5 Profile minimum height :≥ 20mm

6 Profile maximum weight:15KG/ pcs

7 Thinnest position of single point profile:≥ 1.0mm

8 Total equipment power: 3KW

9 Film speed:14-17pcs/min

APPLICATION:

Suitable for all enterprises requiring aluminum profile film application.

✅ Door/Window & Sunroom Profile Manufacturers: Batch-apply film to door/window frames to enhance finished product aesthetics.

✅ Curtain wall aluminum profile manufacturers: Apply high-adhesion protective film to prevent scratches during transportation;

✅ Industrial aluminum profile producers: Apply anti-oxidation film to automation equipment profiles, extending storage life;

✅ Aluminum profile distributors: Offer customized film application services to clients on demand, enhancing product value.

Leveraging advanced technology from Europe and America since 1991, specializes in producing the Jiafa brand packaging machine. Our production spans two workshops, covering 4500m² and 7000m², strategically located in Boai Road, Dali Town, Foshan City, and Longgao Road, Jiujiang Town, Foshan City. Notably, our offerings include the high-efficiency wood grain transfer oven, heat shrink packaging machine, film laminating machine, and wrapping machine, alongside various packaging equipment. Committed to excellence, competitive pricing, and top-notch quality, we've earned a reputation as a leading supplier of heat shrink packaging machines in China.

Key words:

Automatic Profile Film Sticking Machine Film Tapping Machine

Recommended Products