Product classification

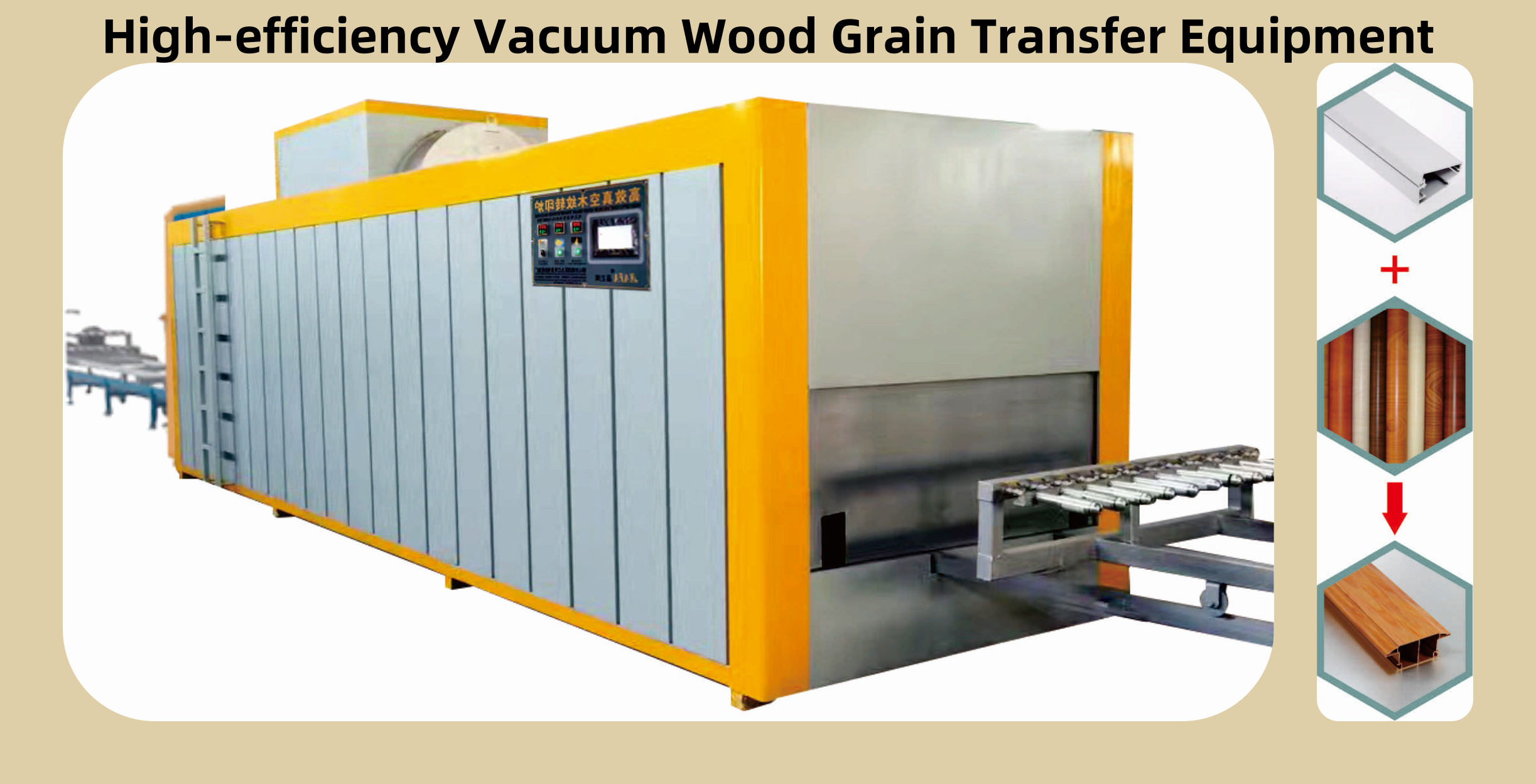

Vacuum Wood Grain Transfer Oven

Our primary offerings include the Jiafa brand high-efficiency wood grain transfer oven, high-efficiency heat shrink packaging machine, film laminating machine, wrapping machine, and various packaging equipment. Additionally, we provide machinery and equipment for aluminum profiles. With a commitment to excellent quality and competitive pricing, we have emerged as a major supplier of heat shrink packaging machines in China.

Categories: WoodGrain Transfer Furnace

Product Introduction

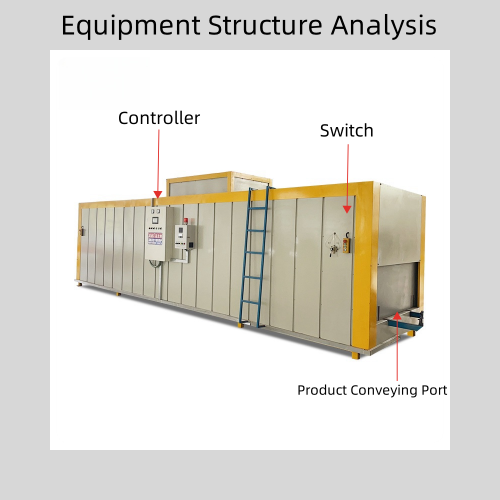

Working principle of gas imitation wood grain production line

1.The wood grain penetration curing furnace is driven by a cycloidal pinwheel reducer to move the roller, which in turn drives the vacuum auxiliary frame to achieve feeding. Through the electrical, temperature control system, operating system, and mechanical parts, the profile enters the furnace for heating via the vacuum auxiliary frame, achieving thermal penetration curing. After curing is completed, it automatically exits the furnace, and after exiting, a reverse blowing film is performed to facilitate quick film removal and improve production efficiency.

In and out of the furnace and temperature control mode: fully automatic. Automatic feeding into the furnace, automatic exiting from the furnace, automatic vacuum shutdown, automatic power shutdown. Four temperature measurement points, four zone temperature control. The temperature difference in six zones is controlled within 5°C to ensure no color difference in the product.

2. Main composition

1. Thermosetting transfer furnace (including burner and heat circulation system) 1 set

2. Vacuum and drive device 2 sets

3. Single transfer cart 2 sets

4. Fully automatic electric control system 1 set

3. Main component technical parameters:

|

Length of transfer aluminum profile |

The first layer of aluminum material from the bottom is 6300mm, the second layer is 6800mm, and the third layer is 7300mm. |

|

Maximum cross-section size of the profile |

Width 100mm * Height 160mm |

|

Output |

About 4-8 furnaces/hour, 3-5 tons/ |

|

Types of transfer paper |

Plastic and pure paper wood grain pattern paper |

|

Process temperature |

150℃-185℃ (using four temperature zone detection) |

|

Curing time |

7-15 minutes (depending on the size and type of paper) |

|

Heating method |

Liquefied gas, natural gas are both applicable or electric heating |

|

Comprehensive energy consumption |

6.5m3--9.0 m3/ t (depending on the size of aluminum material, the gas consumption for transferring 1 ton of aluminum material) |

|

Conveying method |

Automatic/manual |

|

Site area requirements |

(Furnace reference length) 29100mm X (width) 2360mm X (reference height) 3400mm |

|

Furnace body reference size |

(length) 8480mm X (width) 2160mm X (height) 2800mm (Note: Export version height is 2500mm) |

|

Number of transfer profiles (per cart) |

36 pieces + 36 pieces (three layers) |

|

Working power |

12KW (when using high-efficiency electric heating tubes as the heat source, it is 96KW) |

|

Total motor power |

16.5KW |

|

Furnace body outer wall structure |

Overall spray paint, appearance can be customized according to user requirements |

|

Outer wall material |

Made of 2.0mm A3 steel plate |

|

Inner wall material |

Made of 1.5mm A3 galvanized plate |

|

Insulation structure and materials |

Aluminosilicate glass fiber cotton + high-quality glass fiber cotton rock wool with a density of 100Kg, insulation layer thickness is about 230mm, providing excellent energy-saving insulation effect. |

|

Air circulation method |

Downward supply and upward recovery circulation method, adjustable air outlet. |

|

Air duct material |

Made of 1.5mm galvanized plate, hydraulically bent. |

|

Furnace chamber entrance reference size |

Width 1690~2170, height ≥720. |

Leveraging advanced technology from Europe and America since 1991, specializes in producing the Jiafa brand packaging machine. Our production spans two workshops, covering 4500m² and 7000m², strategically located in Boai Road, Dali Town, Foshan City, and Longgao Road, Jiujiang Town, Foshan City. Notably, our offerings include the high-efficiency wood grain transfer oven, heat shrink packaging machine, film laminating machine, and wrapping machine, alongside various packaging equipment. Committed to excellence, competitive pricing, and top-notch quality, we've earned a reputation as a leading supplier of heat shrink packaging machines in China.

Key words:

Vacuum Wood Grain Transfer Oven

Recommended Products