Efficient bagging, significantly speeding up the packaging of single-strand profiles.

Time: 2025-01-14

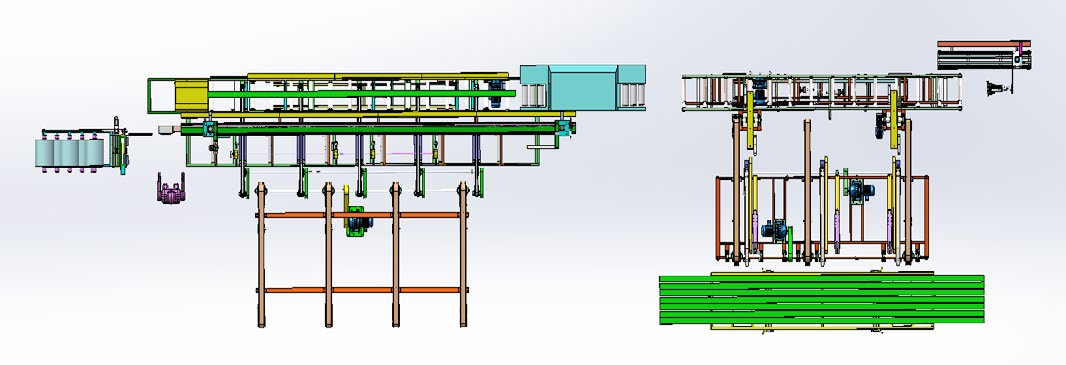

Aluminum Profile Automatic Single Bagging Machine

1. Purpose:

- Product ProtectionAfter the aluminum profile processing is completed, single bagging can prevent the surface of the profile from being scratched, contaminated with dust, and corroded. For example, for aluminum profiles used in construction, such as door and window frames, bagging can avoid damage from external factors during transportation and storage, ensuring the quality upon arrival at the construction site.

- Facilitates Identification and ClassificationAfter bagging, labels can be affixed to the bags to indicate the model, specifications, batch number, and other information of the profiles, making it easier to classify and locate them during warehouse management and subsequent processing. Clear identification helps improve production efficiency when industrial aluminum profiles are used for manufacturing different equipment.

2. Performance

- Precise BaggingSingle bagging machines typically have a high-precision positioning system that can accurately place the bag on the aluminum profile. It can automatically adjust the bagging position and method according to the length, shape, and size of the profile, ensuring the bag fits tightly to the profile, with an error generally controlled within ±5mm.

- Flexible Speed AdjustmentThe bagging speed can be adjusted according to actual production needs. Generally, the bagging speed of a single bagging machine is around 1 to 10 bags per minute, allowing companies to flexibly set the speed based on order volume and delivery deadlines to achieve optimal production efficiency.

- Strong Bag AdaptabilityIt can accommodate bags of various materials and sizes. Whether plastic film bags, paper bags, or composite material bags, as long as the bag size is within the machine's specified range, bagging can proceed smoothly. The width of the bags can generally be adjusted between 100 - 500mm, and the length can adapt between 500 - 5000mm.